| |||||||||||||

| |||||||||||||

| QUICK VOTE | ||||

|

|

||||

| NEW FROM LASER FOCUS WORLD | ||||

| Webcast Archive: Optical Fiber Solutions presents "Laser Optimized Multimode Fibers" from KMI Research's Newport Conference Dovebid Equipment Auctions Try our new used equipment auctions! Powered by DoveBid |

||||

|

| ||

| Newsbreaks | ||

| Nitrogen lowers threshold current in quantum-well lasers | ||

|

Dilute-nitride quantum-well (QW) structures show promise for use in 1300-nm-emitting semiconductor lasers, including vertical-cavity surface-emitting lasers. Indium gallium arsenide nitride QW lasers grown with metalorganic chemical-vapor deposition (MOCVD) are potentially lower in cost than those grown with molecular-beam epitaxy, as high-quality distributed Bragg reflectors are easier to fabricate with MOCVD. A group at the University of Wisconsin (Madison, WI) has created 1295-nm-emitting lasers using MOCVD; the edge emitters have threshold and transparency current densities of 211 and 75 A/cm2, respectively—the lowest values reported to date, according to the researchers. | ||

|

Incorporating nitrogen into the QW while maintaining a high-quality optical film is difficult. The researchers reduce the nitrogen content to 0.5% and increase indium content to 40% in a strain-compensated QW to achieve long-wavelength emission. The devices exhibit relatively low temperature sensitivity, with T0 values (a measure of temperature sensitivity in which a higher value, in degrees Kelvin, indicates lower sensitivity) of 82 K to 90 K for cavity lengths of 720 to 2000 µm and temperatures of 20°C to 60°C. Contact Nelson Tansu at tansu@cae.wisc.edu. | ||

| Russian Academy quantifies the destruction of chalcogenide fiber | ||

|

The use of optical amplifiers in fiberoptic communications has led to high optical powers in these systems of up to 1-W continuous-wave. For silica-based fiber, such powers can cause an optical discharge in the fiber core, resulting in catastrophic destruction. Now, scientists at the Russian Academy of Sciences (Moscow, Russia) have characterized fluoride and chalcogenide optical fibers with respect to damage thresholds to investigate these newer materials for use in fiber lasers and amplifiers. | ||

|

In catastrophic destruction of silica fiber, a discharge plasma appears in the fiber as a bright white spot that propagates from a hot spot in the fiber back toward the light source. Whereas silica fiber experiences destruction at a rate of 1 m/s at 1-W laser powers in the core, chalcogenide and fluoride fibers are destroyed at a rate 1000 times slower—1 mm/s—and the entire cross section of the fiber is melted. However, the threshold laser power necessary to destroy chalcogenide and fluoride fiber, 10 mW, is 10 times less than that of silica fiber and is strongly dependent on environmental temperature. Contact Evgueni Dianov at dianov@fo.gpi.ru. | ||

| Microspheres position photonic-crystal layers | ||

|

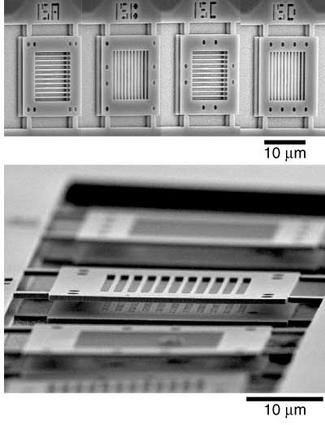

Photonic crystals (PCs) operating in the visible or near- to mid-infrared spectral regions can be created by photolithography or colloidal self-assembly of uniformly sized particles. These methods, however, are restricted in flexibility, limited either by etching of many-layered structures in photolithography or by lack of precise control of individual element placement in colloidal self-assembly. Japanese researchers at Riken (Saitama), the National Institute for Materials Science (Ibaraki), and Yokohama National University (Kanagawa) have developed a method of constructing PCs based on photolithography that requires only etching single-layered structures, simplifying the layers' fabrication and retaining precise control of features such as defects that can become waveguides or laser cavities. | ||

|

The researchers assemble PCs one level at a time using separately fabricated layers and micromanipulating them to properly position them. The layers, which are made of indium phosphide, are stacked using a small number of polystyrene microspheres as reference pins, with the spheres put into place by a probe that has a tip thickness of 0.5 µm. The microspheres are located between each level in holes in each PC layer. A tightly interlocked PC stack is built up with a maximum positioning error of 50 nm. Contact Kanna Aoki at kanna@postman.riken.go.jp. | ||

| Quantum-cascade lasers become photodetectors | ||

|

Because their mid-infrared emission transmits well through the atmosphere, quantum-cascade (QC) lasers are being investigated for use in free-space optical communications. The traditional type of light sensor paired with such a laser is a mercury cadmium telluride interband photodetector; quantum-well infrared detectors (QWIPs) could also be used. But a detector fabricated with materials and structure similar to those of a QC laser would allow monolithic integration of light source and detector. Researchers at the Institute of Physics (Neuchâtel, Switzerland) are testing this approach by creating intersubband photodetectors that have QC-laser structures. | ||

|

Two devices were fabricated. One has a 5.3-µm two-photon-resonance structure, while the other is a 9.3-µm bound-to-transition laser. The former works at temperatures up to 325 K and has a responsivity of 120 µA/W at 2200 cm-1, while the latter works to 297 K and has a responsivity of 50 µA/W at 1330 cm-1. The absorption peak of these devices can be shifted by applying an external bias. Although the responsivity of these devices is small compared to QWIPs, their noise gain is also very small, a possible compensation. Contact Daniel Hofstetter at daniel.hofstetter@unine.ch. | ||

| Matching materials reduce misalignment of polymer-lens arrays | ||

|

One of the many ways to couple the light from one set of optical fibers into another is to use a polymer linear lens array. In a version of this device developed at Matrix (East Providence, RI), up to 12 sets of spherical lens pairs are spaced equally on a straight line. While the lenses themselves are molded of an infrared-transparent material, the lead coupling units that hold the fibers in place are usually molded of a reinforced and glass-filled plastic. The coefficients of thermal expansion (CLTE) of these two materials—and the CLTE mismatch between them—determine how well the fibers stay aligned to the lenses as temperature changes (Telcordia specifications state that assembled arrays must perform satisfactorily over a -40°C to +150°C range). | ||

|

John Medgyesy of Matrix has completed a study of the various polymers and their combinations used in linear lens arrays. He found, for instance, that the CLTE mismatch between Ultem (a lens-array material) and Fortron (a coupling-unit material) was one-third that of some other combinations, aided partly by Forton's glass-transition temperature of 90°C. His study adds CLTE to the characteristics that device designers should consider. Contact John Medgyesy at jm33@matrixinc.net. | ||

| Fiber laser welds aluminum | ||

With output powers now in the kilowatt range, fiber lasers have entered the industrial arena. A 2-kW fiber laser developed by IPG Photonics (Oxford, MA) and installed in a Kuka Schweissanlagen (Augsburg, Germany) robotic system has demonstrated success in welding aluminum as well as steel. Welding aluminum using lasers has been a long-term challenge because ofthe metal's high reflectivity, but the high beam quality of the fiber laser—which produces energy densities of 30 MW/cm2 and focused spot sizes of smaller than 300 mm—makes such a process possible. The laser is currently being evaluated for production fabrication of automobile bodies. | ||

|

The laser actually consists of building blocks that are 1.1-µm-emitting 100-W single-mode fiber lasers, with all outputs channeled into a fiber delivery system that has a core diameter of 300 µm. The resultant output has a beam parameter (M2) of 12. The anticipated lifetime of the system is greater than five years. Fiber lasers in general provide straightforward delivery of light to industrial tools that must move. Contact Valentin Gapontsev at vgapontsev@ipgphotonics.com. | ||

| Laser Focus World December, 2002 | ||

| BUYERS GUIDE | ||||

|

||||

| CURRENT ISSUE | ||

|

||