3D photonics

Photonic crystals — optical analogues of

electronic semiconductors — hold great promise for

manipulating and processing light signals in future

photonic devices. A new 3D microassembly technique could

greatly aid the development of photonic crystals for

such applications.

6 February 2003

Ed Gerstner

|

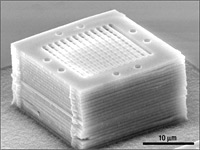

| Scanning electron micrograph of

one of the authors' 3D photonic crystal

structures. Multiple plates are patterned using

standard lithographic and etching techniques,

and then assembled into a stack using fine

mechanical probes. | |

|

The tremendous progress in electronics that has

occurred over the past 50 years has, to a large extent,

been made possible by the unique electronic bandgap

structure of semiconducting crystals such as silicon.

Consequently, there has been great interest in the

development of optical analogues — known as photonic

crystals — to electronic semiconductors. Photonic

crystals offer the possibility to achieve the same

control over light as can be achieved over electrons,

but in practice they are notoriously difficult to design

and construct. In Nature Materials this month,

Kanna Aoki and colleagues demonstrate a novel

fabrication method that makes it possible to assemble

three-dimensional photonic crystal structures at the

microscopic scale.

Photonic crystals are periodic structures formed at

micro- and submicrometre scales that influence the

propagation of light waves in a manner similar to that

in which atomic crystals influence the propagation of

electron waves. The main goal of much research into

photonic crystals is the formation of a photonic

bandgap. The simplest of photonic bandgap structures is

the fibre Bragg grating, in which periodic variations in

refractive index introduced along an optical fibre

restrict the propagation of certain wavelengths within

the fibre. Such bandgap behaviour has now also been

demonstrated in two dimensions in a variety of planar

waveguide structures. But achieving the formation of a

photonic bandgap in three dimensions has so far proved

elusive.

The main obstacle to making photonic crystals that

exhibit true 3D photonic bandgap behaviour is the

difficulty in constructing 3D periodic structures with

the precision and control required to avoid physical

defects that degrade their optical properties. In an

attempt to overcome this, Aoki and colleagues have taken

an approach that minimizes the chances of such defects

being introduced. They start by fabricating a series of

2D grid structures from indium phosphide by conventional

lithographic and etching techniques. These grid plates

are then stacked on top of each other using fine

mechanical manipulator probes, and then aligned and

secured using polystyrene microspheres that act as

microscopic rivets when placed in alignment holes

situated in each of the plates (see figure).

By patterning all the fine structures of their

photonic crystal in a single lithographic step, the

authors significantly improve their control over the

fabrication process. This enables them to achieve a

spatial precision of less than 50 nm. Moreover, the

flexibility of the microassembly approach allows them to

actively engineer specific defects into their photonic

crystal — analogous to the introduction of specific

dopants into the atomic lattice of a semiconductor.

Although their present structures do not yet achieve

a full 3D bandgap, they do demonstrate a significant

decrease in the transmission of infrared wavelengths in

the range of 3–4.5 µm. More significantly, demonstration

of the use of microassembly techniques to create such

structures opens up new avenues for the development of

not only true 3D photonic crystals, but a whole host of

complex 3D micro- and nano-scale structures. |